Introduction to different nonwoven fabric topsheet of diapers

Jan 24, 2025

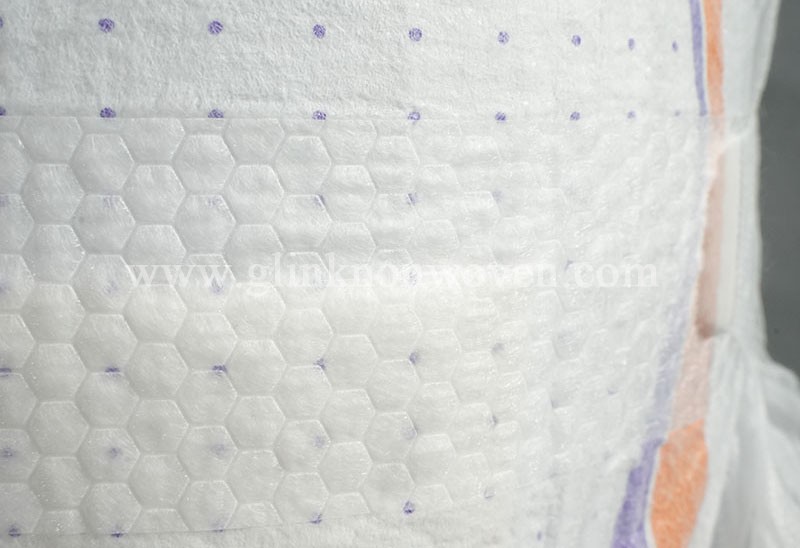

Spunbond nonwoven fabric, hot air nonwoven fabric and thermal bond nonwoven fabric can all be used as the topsheet materials of diapers, and they each have different advantages and disadvantages. The following is a detailed analysis of these three materials:

1. Spunbond nonwoven fabric

Advantages: Spunbond nonwoven fabric has high strength, good elongation at break and tear strength, which makes diapers less likely to break during use. Spunbond nonwoven fabric is relatively thin, which helps to reduce the overall weight of diapers and improve the comfort of wearing.

Disadvantages: Compared with hot air nonwoven fabric, spunbond nonwoven fabric is slightly inferior in softness and breathability, which may cause a certain friction to the baby's delicate skin and affect breathability.

2. Hot air nonwoven fabric

Advantages: Hot air nonwoven fabric has high fluffiness and elasticity, which makes the surface of diapers fit the baby's skin better and provide better comfort and wrapping. Hot air non-woven fabrics are soft to the touch and will not cause excessive friction on the baby's skin. At the same time, they have good warmth retention and are suitable for use in colder environments. Hot air non-woven fabrics have good air permeability and water permeability, which helps keep the inside of the diaper dry and reduce the risk of red bottom.

Disadvantages:

Low strength and easy deformation: The strength of hot air non-woven fabrics is relatively low and it is easy to deform during pulling, so more frequent changes may be required to maintain the integrity of the diaper.

3. Thermal bond non woven fabric

Advantages: The production process of thermal bond non woven fabric is relatively mature and the cost is low, so the price is relatively affordable.

Disadvantages: Hard feel and average breathability: Compared with hot air non-woven fabrics, thermal bond non woven fabric may feel slightly harder and have average breathability, which may not be suitable for babies with high comfort requirements.

(Note: Thermal bond non woven fabric is relatively rarely used on the topsheet of baby diapers, and are more commonly used in the medical and health fields. The reason for mentioning them here is to provide comprehensive information.)

Summary: When choosing the surface material of diapers, you need to consider factors such as the baby's skin condition, activity level, and seasonal changes. If the baby has delicate skin and requires high comfort, you can choose hot-air non-woven fabrics as the surface of diapers; if the baby has a large amount of activity and needs stronger mechanical support, you can choose spunbond non-woven fabrics as the surface of diapers. At the same time, you also need to pay attention to the frequency of diaper changes and cleaning care to keep the baby's skin healthy and comfortable.

Read More