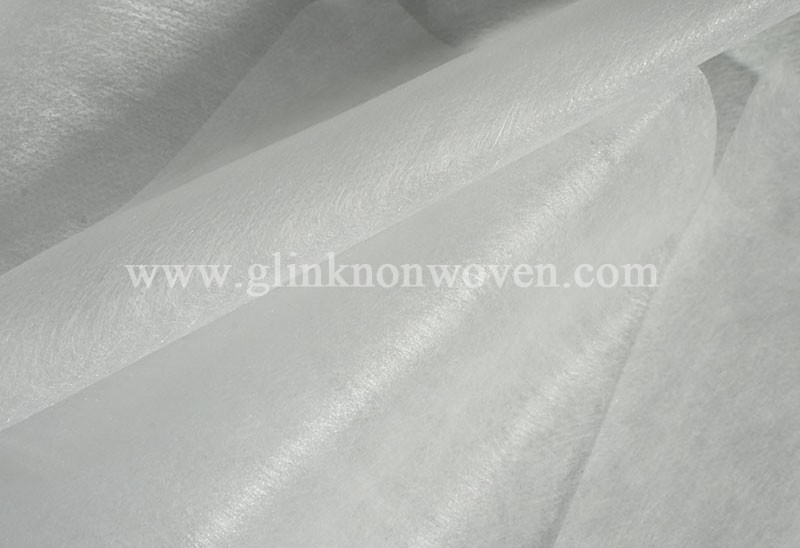

Application of thermal bond nonwoven fabrics in diapers and sanitary napkins

Dec 30, 2024

Thermal bonded nonwoven plays an important role in the manufacture of personal hygiene products.

In the manufacture of diapers, it is not only often used as a material for wrapping the core to ensure the stability of the polymer absorbent material, but also as a diaper topsheet material. With its light, thin and soft characteristics, it greatly reduces the friction on the baby's skin. At the same time, its excellent breathability helps prevent diaper rash, and its high strength improves the overall durability of the diaper.

In the field of sanitary napkins, thermal bonded nonwoven also performs well. It can be used as a sanitary napkin topsheet material (sanitary napkin surface material) to provide a soft and skin-friendly touch, effectively prevent side leakage, and because of its excellent moisture absorption and breathability properties, it can quickly Drain menstrual blood and keep skin dry and comfortable.

In addition, the thermal bonded nonwoven fabric that has undergone special antibacterial treatment further reduces the risk of infection during use, and its light, thin and soft characteristics make the sanitary napkin lighter and more close-fitting.

In summary, the application of thermal bonded non-woven fabrics not only significantly improves the safety and comfort of diapers and sanitary napkins, but also effectively enhances the durability and overall performance of the products, becoming an indispensable key material in the manufacture of personal hygiene products.

Read More