Introduction about panty-type sanitary napkins

Feb 19, 2025

Safe pants, also known as sleeping pants, night pants, panty-type sanitary napkins, etc., are a kind of menstrual products designed for women.

1. Design and material

Design: The design of safe pants imitates small underwear, which can wrap the buttocks in all directions and provide 360-degree protection without dead angles.

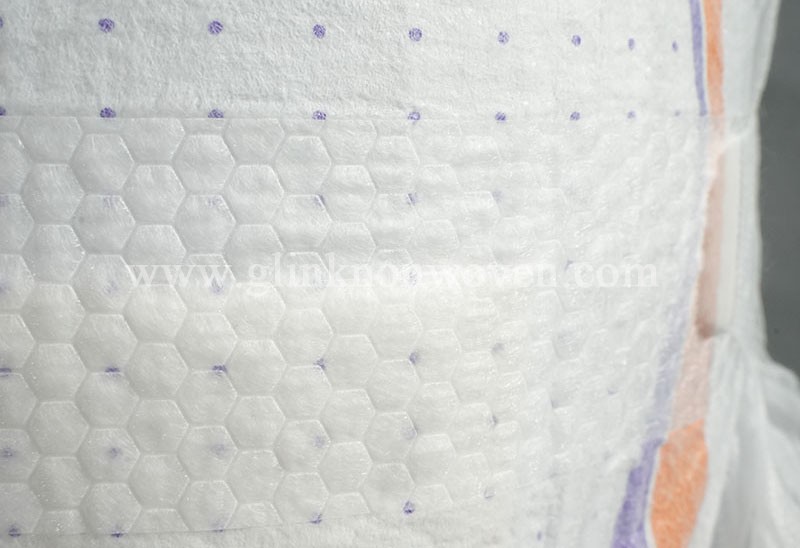

Material: Safe pants are usually made of non-woven fabrics, printing PE films and other materials, and the topsheet layer is made of soft and skin-friendly materials, which gives users a comfortable touch.

2. Applicable scenarios

Nighttime use during menstruation: Safe pants can provide better protection during women's menstrual period, especially at night with heavy menstrual flow, to prevent menstrual blood from leaking and soiling sheets and bedding, so that women can sleep peacefully.

Postpartum lochia period: The mother will discharge lochia within a few days after delivery. Safe pants can help the mother better manage lochia, keep the private parts clean and hygienic, reduce the number of times to change underwear, and reduce the physical burden of the mother.

Special period: For some women who need to stay in bed and have difficulty in moving due to physical reasons, safe pants are also a convenient choice, which can keep the body clean and comfortable at any time. In addition, in special circumstances such as long-distance travel, long car rides, and outdoor activities, safe pants can also provide long-term protection.

3. Advantages

Strong absorption capacity: safe pants usually have a large absorption capacity, can quickly absorb menstrual blood and other liquids, keep the surface dry, and reduce dampness and discomfort.

Good leak-proof effect: Its unique trouser design and good fit can effectively prevent side leakage and back leakage, allowing women to feel more at ease when sleeping or moving.

Comfortable to wear: safe pants are generally made of soft cotton or non-woven fabrics, which are skin-friendly and will not irritate the skin. At the same time, the elastic band design of the waist and trouser legs can also ensure the comfort of wearing without tightness.

Convenient replacement: safe pants are disposable products, which can be directly discarded after use without washing, which is very convenient.

4. Key points for purchase

Pay attention to the material: Choose a material with good breathability, soft and comfortable to reduce irritation and discomfort to the skin.

Pay attention to the size: Choose the right size according to your hip and waist circumference. Too tight or too loose may affect the use effect and even cause side leakage and other problems.

Choose a regular brand: There are many brands of safe pants on the market. You should choose regular brands with good reputation. Products of regular brands are more guaranteed in terms of quality and safety. You can refer to the evaluation of consumers and the evaluation results of professional institutions.

5. Precautions for use

Replace in time: Although safe pants have strong absorption capacity, they cannot be left unchanged for a long time. It is generally recommended to change them every 2 to 4 hours to keep the private parts clean and dry, avoid breeding bacteria and cause infection.

Pay attention to hygiene: Clean your hands before wearing safe pants to avoid bringing bacteria to the pants. At the same time, do not touch the crotch to prevent contamination.

Storage method: Unused safe pants should be stored in a dry and ventilated place, avoid moisture or direct sunlight to avoid affecting the performance of the product.

6. FAQ

Can safe pants be worn during the day: safe pants can also be worn during the day, but some people may be allergic to the material of safe pants, causing skin redness, itching and other discomfort symptoms. If you are prone to allergies, it is recommended to check the ingredient list of the product before use, or choose milder products such as fragrance-free and fluorescent-free products.

Can safe pants be worn all night: Although safe pants have a large absorption capacity, it is not recommended to wear them all night without changing if the menstrual flow is particularly heavy. It is still necessary to change them in time according to the actual situation to keep them dry and hygienic.

Can pregnant women wear safe pants: Pregnant women can wear safe pants, especially as the abdomen gradually increases during pregnancy. The loose design of safe pants can adapt to the changing body shape of pregnant women and provide better comfort and support. However, products with good breathability and safe materials should be selected, and they should be replaced in time.

What is the difference between safe pants and diapers: safe pants are specially designed for women during menstrual period or postpartum lochia period, and they pay more attention to absorbing menstrual blood and lochia. Diapers are mainly designed for infants and young children to absorb urine. In terms of size, absorption speed, leak-proof design, etc., safe pants and diapers are different.

In summary, safe pants are a convenient, practical and comfortable product for women during menstrual period. Paying attention to the above points and precautions when purchasing and using can help women spend their special period with greater peace of mind.

Read More