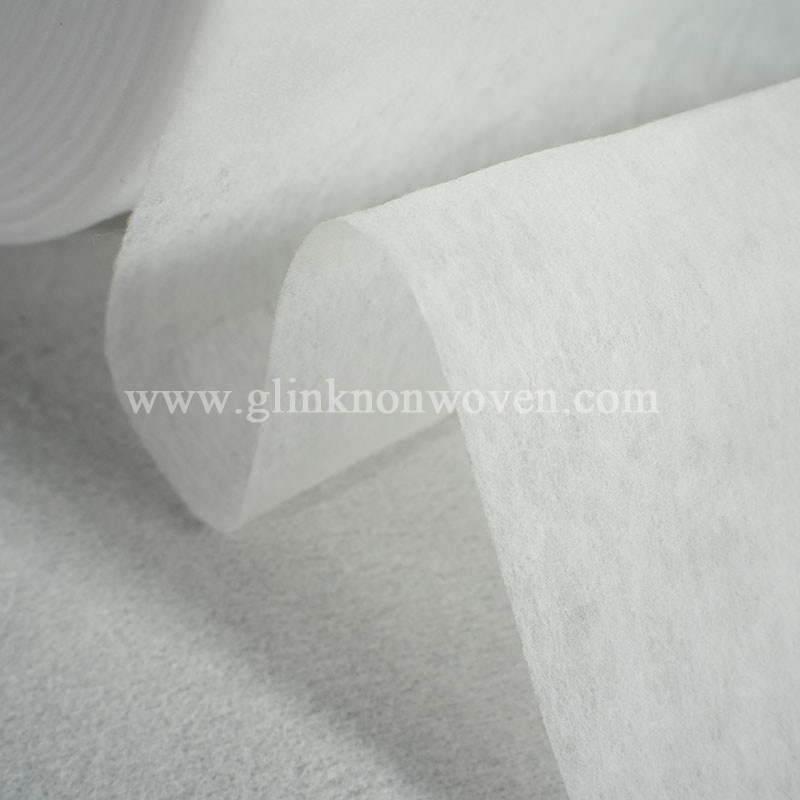

The main functions of diaper absorbent core include rapid absorption, uniform dispersion, keeping dry, anti leakage, and reducing side leakage. The core is the key part of diapers that absorbs urine, and its performance directly affects the effectiveness of diaper use and the comfort of babies.

English

English English

English Español

Español عربي

عربي

IPv6 network supported

IPv6 network supported